PRODUCTS

- SHEET METAL MACHINERY

- PRODUCTS

- Turret Punch Presses [M3048TG / M3058TG / M30510TG]

MOTORUM M3048TG / M3058TG / M30510TG

M3048TG / M3058TG / M30510TG

The New 30 Ton Solution

Latest Technology from the Inventor of the Electric Turret Punch Press.

|

|

Pyramid Base Design

Stability at maximum tonnage.

Muratec “Green” Machine

Environmentally friendly and power efficient.

Latest Process Integration Options

Reduce post processes with the latest machine and tooling technology. Supports tapping, forming, marking, deburring and various automation options.

Intelligent Control

New touch screen user interface assists the operator and increases machine productivity.

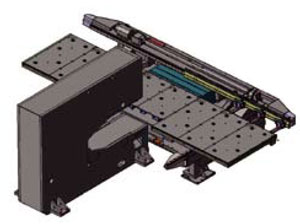

Two Piece Design

| Muratec’s original “C” frame is designed to separate the frame and table base. Even at maximum tonnage, vibrations are not carried over to the table delivering increased precision and high quality parts. |  |

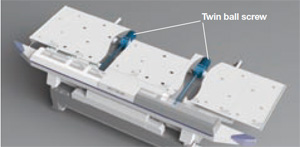

Wide Tabel Base & Y-Axis Twin Ball Screws

| A wide frame structure supports the 2.5M X-axis stroke table. Twin Y-axis balls screws are controlled by synchronized servo motors. Both have been engineered to realize improvements in stability and processing accuracy during high-speed movements. |  |

In-Line Pnch Drive Design

| Driven by Muratec’s goal of constant improvement, the ram servo motor has been designed parallel with the press frame. This provides a compact press frame generating less stress, greater rigidity, improves hole quality and tool life. |  |

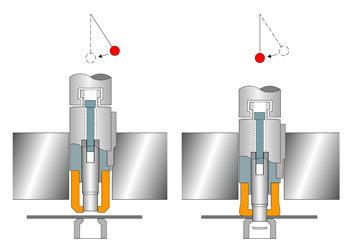

Positive Strip Tooling Is A Proven Wiedemann Design

| Using a mechanical link between the ram and the punch holder provides a positive push and pull motion during the entire punching stroke. The design has been field proven for its high strength, precision and simplicity of tooling. It provides the most economical tooling solution in the industry. Also available is high end guided tooling with steel strippers providing precision production and longer tool life. |  |

Forming

Optimum control of RAM speed leads to fast and accurate forming of the highest quality, with work very minimal distortion.

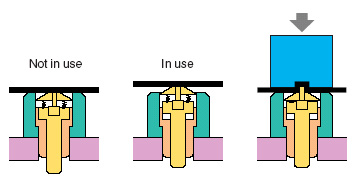

Retractable forming die function (Option)

Upward forming tool dies are retracted out of the way of the work sheet movements when forming is not in operation to avoid interference of forming die with workpieces or workholders. This allows free fast movement of the sheet without any restrictions and improves quality.

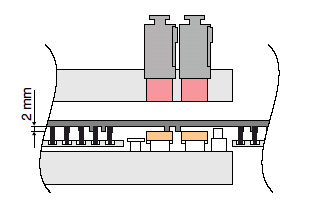

Downward extrusion protection (Option)

Forming with thrust from below does not lift the work, allowing extrusion and other high-precision forming processes.

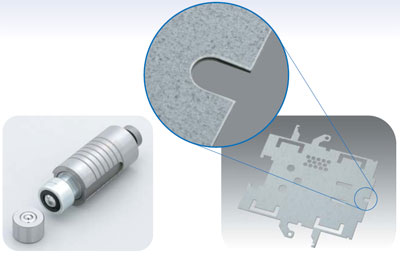

Deburring Operation

One tooling. All round deburring operation (Option)

Deburring and pinching operation using the ball bearing manufactured originally by Muratec. Two bearings from top and bottom sides removes the burr of the edge both sides, upper and lower, of the punched parts simultaneously by pinching the edge of the punched sheet along with the path.

Indexable Varitool

| The Indexable Varitool (Option) comes in a 12 tool configuration and allows all tools in the Varitool to be indexed 360°. Each tool is programmed like a separate auto index station. Any X or Y offset is automatically compensated for by the control. |

|

Other Options

Tapping Units

- 4-Station Tapping Unit

- 8-Station Tapping Unit

- Tapping Vacuum Unit

- Tapping Tool Life Monitor

Tooling

Main Specifications

| Model | M3048TG | M3058TG | M30510TG | |

|---|---|---|---|---|

| Punching capacity | 300 kN 30.6 Metric Tons 33.6 US Tons |

|||

| Maximum sheet thickness | 6.35 mm [0.250"] | |||

| Maximum sheet size punchable without repositioning (Y x X) |

1250 mm x 2500 mm [49.21" x 98.43"] |

1525 mm x 2500 mm [60.04" x 98.43"] |

1525 mm x 3050 mm [60.04" x 120.1"] |

|

| Hit rate | 25 mm pitch 7 mm stroke |

510 hpm | ||

| 0.5 mm pitch 1.4 mm stroke |

1000 hpm | |||

| Punching accuracy | +/- 0.1 mm [+/- 0.004"] | |||

For your inquiry : Please consult your local Muratec sales networks for information regarding the products and services that may be available in your area.