|

LS3015HL / LS2512HLAdvanced Hybrid LaserLS3015HL / LS2512HL

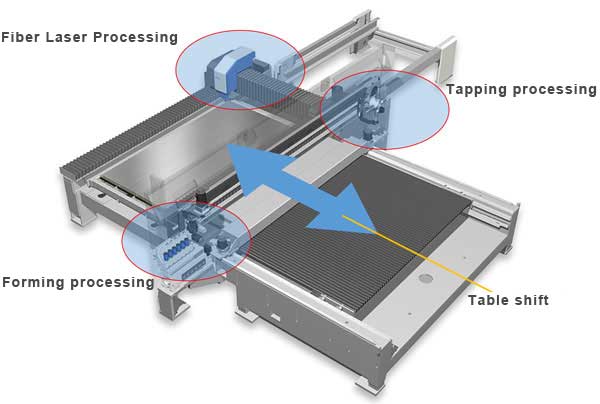

The LS3015HL / LS2512HL Hybrid Laser is the latest innovation in Muratec's pursuit of value-added sheet metal processing. Leveraging the high-speed precision of fiber laser cutting and the accurate forming and tapping performance synonymous with Muratec's punch press technology, the Hybrid Laser provides superior quality and significant throughput increases.

|

||||||||||||||||||||||||||||||||||||||||||

|

LS3015HL |

LS2512HL |

|---|---|---|

Rated output |

2500 W, 4000 W, 6000 W |

|

Maximum cutting area (X×Y×Z) |

3075 mm × 1550 mm × 100 mm |

2525 mm x 1265 mm x 100 mm |

Maximum material weight |

920 kg |

620 kg |

Fast traverse speed |

170 m/min. (XY simultaneous) |

|

Positioning accuracy |

+/- 0.01 mm | |

Repeat accuracy |

+/- 0.01 mm | |

Forming unit

Maximum processing capacity |

5 ton |

|---|---|

Number of forming stations |

8 |

Tooling type |

LS3015HL / LS2512HL special tooling |

Maximum forming sheet thickness (*) |

6.35 mm , 12 mm (option) |

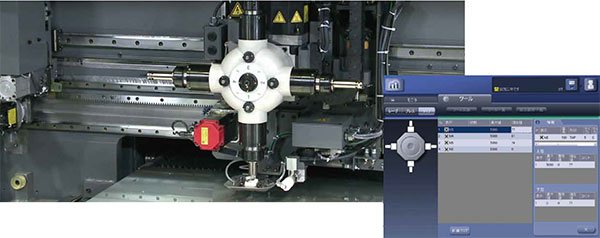

Tapping unit

Number of tapping stations |

4 (standard), 8 (option) |

|---|---|

Tap size range |

M2 - M10, M12 (option) |

Type of tap |

machine tap or rolling tap |

Maximum tapping sheet thickness (*) |

6.35 mm, 12 mm (option) |

* This shows possible loading work dimensions for forming & tapping, but not capability of forming & tapping.

For your inquiry : Please consult your local Muratec sales networks for information regarding the products and services that may be available in your area.